Fixing the Pump Pressure of the Rancilio Silvia Espresso Machine

Miss Silvia, as she’s sometimes affectionately called in coffee circles, has been an invaluable companion these past years. But last Friday she started acting up: Suddenly, there wasn’t enough pressure to push hot water through the portafilter, only a slow drip from the group head. It was time to investigate.

Miss Silvia

Miss Silvia

The two big strengths of the Rancilio Silvia espresso machine are its simplicity and durability. She’s made from few, high-quality components, designed, manufactured and assembled with Italian precision. No obscure, sealed-off or glued-together parts, no impossible-to-replace power electronics. The machine was introduced in 1997 and has since received a few thoughtful updates - the latest being V6, which I bought in 2020. 28 years after the machine’s introduction, spare parts for all components are readily available online and there is an active modding community. All that to say: If you take good care of Miss Silvia, she will last a lifetime.

Enough stanning, let’s find and fix the problem. Right after the mandatory…

Disclaimer: Do not tinker with your coffee machine unless you know what you’re doing. Never touch the inside of the machine when it’s powered on. Before you unscrew or clean components, unplug the main power chord. Don’t get water near electronic parts. I am not responsible for you dying. You have been warned ;-)

Finding the Problem

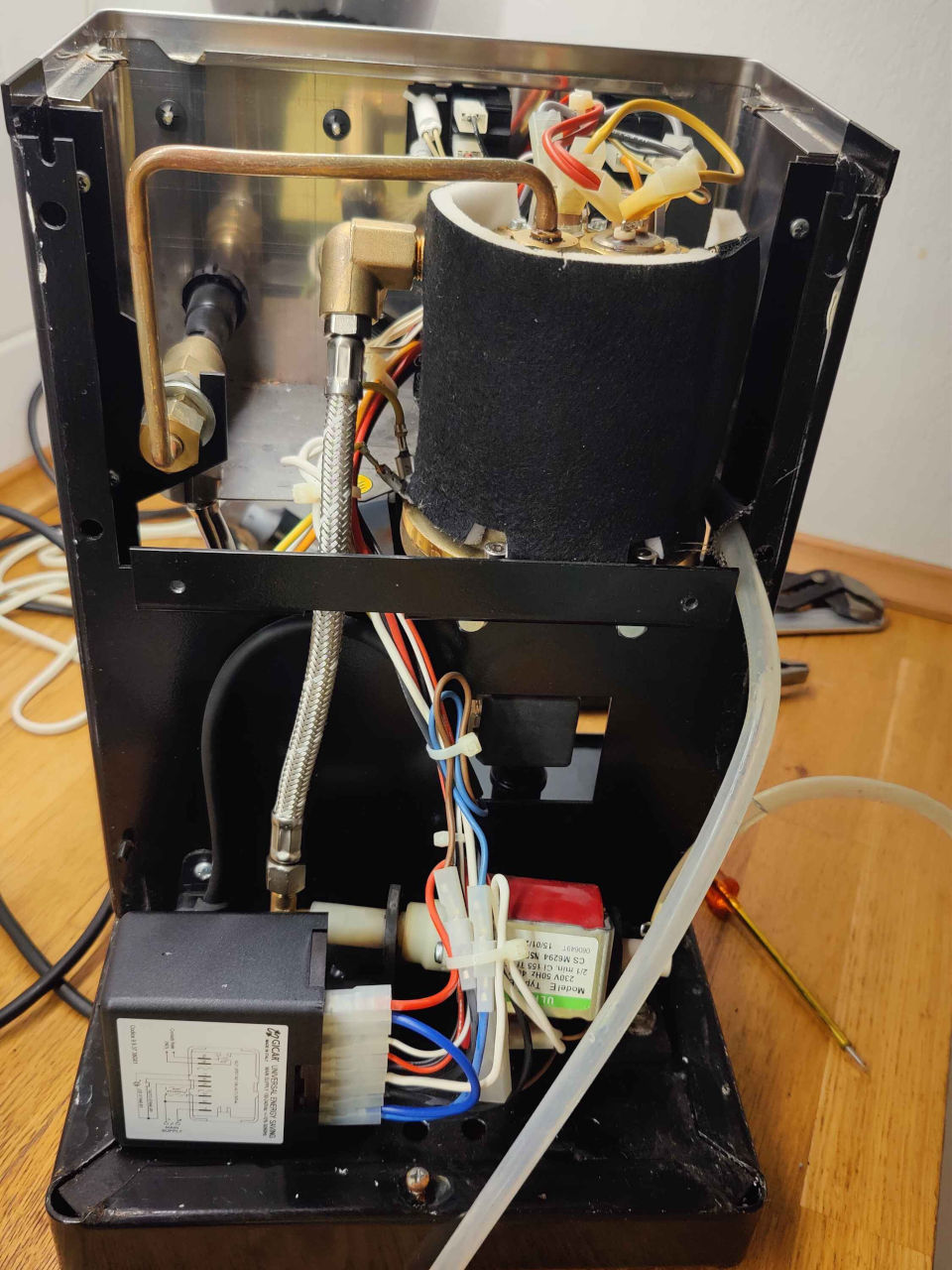

A quick search revealed that a lack of pressure at the group head could have three underlying causes: A defective pump, a broken/clogged solenoid valve or a leak in the hoses/pipes/connections. To get a better look at the components, I removed the back cover of the machine, which turned out to be suprisingly simple.

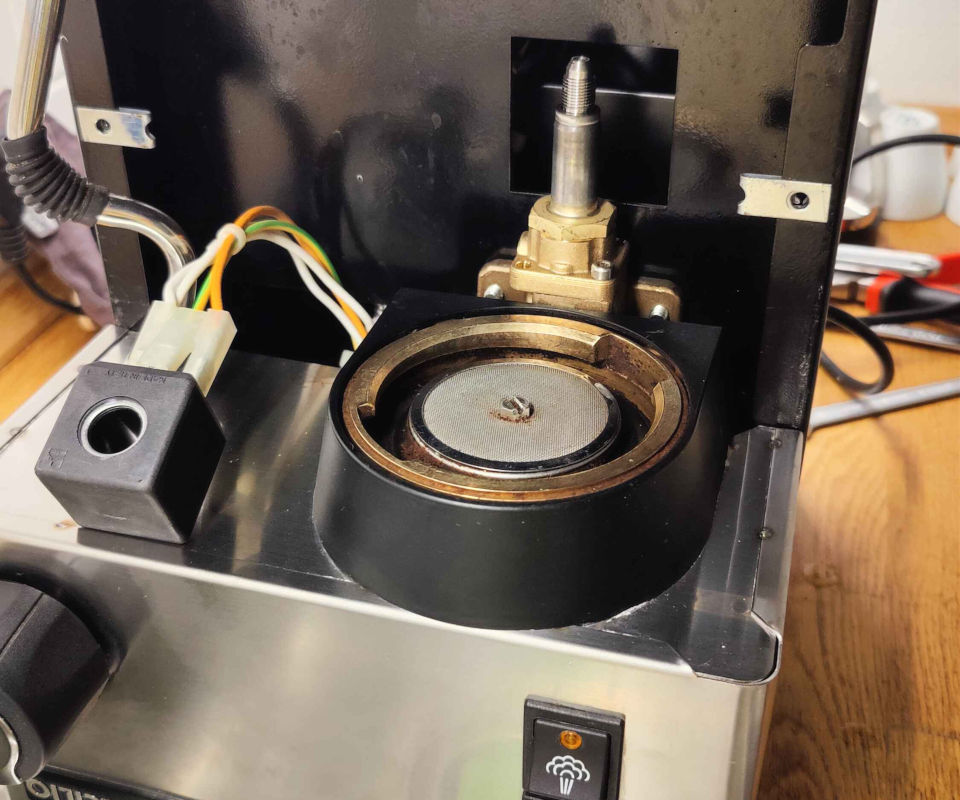

I also removed the lower front cover, which revealed the solenoid valve:

With the water tank placed next to the machine and both hoses in the tank, I then switched on the hot water delivery (the second button from the top). This mode is intended for drawing hot water through the steam wand, e.g. for making Americano or tea. But if you keep the steam wand closed it will simply cycle water through the machine, which is great for cleaning or … well, checking for leaks and proper pump functionality. I was able to confirm that the pump sounded normal, it was drawing water as expected and there were no leaks.

That left the solenoid valve. When dispensing coffee water (the first button from the top), the valve was audibly clicking, so it didn’t seem broken. It also didn’t seem to be leaking during dispensation. But, as suggested by countless repair stories in user forums, a bit of sludge in the valve would be enough to prevent it from shutting properly and thus cause the pressure drop I was experiencing at the group head. The diagnosis for Miss Silvia was clear and so was the treatment: A proper cleaning of the solenoid valve.

Fixing the Problem

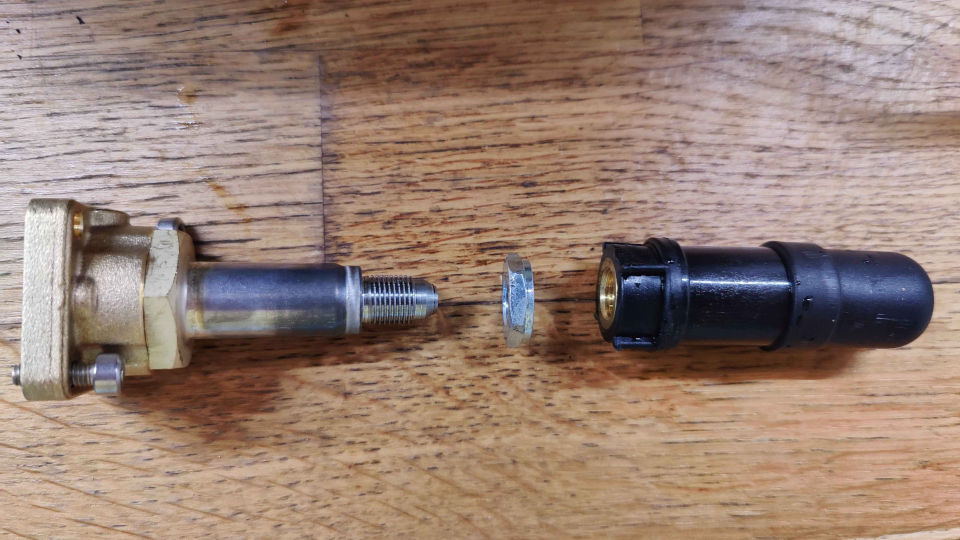

Taking the solenoid valve apart is easy once you know how to do it. You may want to turn the machine on its side or even upside down. You then have to screw off these three parts:

The black part is the drip outlet. You can screw it off by hand, possibly after giving it a slight nudge with a wrench (14mm I believe, but uncertain as I used an adjustable wrench).

The silver ring holds the coil block in place (its direction is reversed in the photo, the small end should point to the left). Again, you can loosen it with slight twist of a wrench, then screw it off by hand.

Once you have removed the first two parts, you can slide off the black coil block:

The third part is the valve itself and you remove it by taking out the two shoulder screws with a 3mm Allen key:

And, lo and behold, the disassembled valve revealed quite a bit of limescale sludge:

I submerged the valve in lemon-based limescale remover and rinsed it a bunch of times. This got rid of the sludge inside the valve. Side note: You’ll always want to use natural removers instead of chemical ones for cleaning as tiny amounts of residue are bound to end up in your drink.

Next, I dripped a bit of limescale remover into the hole that connects to the valve in the upper part of the group head (still turned upside down). This resulted in a very satisfying “volcano” of sludge erupting from the hole (see video below). I wiped away the sludge and repeated this a number of times until no more goo was coming out and I thought the valve connection was sufficiently clean.

Finally, I screwed everything back together, sat the machine upright, put the tank back in and ran a full cleaning cycle with the blind screen portafilter. More dirt and sludge came out through the solenoid valve at the bottom which was a good sign. The water pressure at the group head was not super strong but seemed better. When the water was completely clean, I let the machine sit for a bit and then pulled an espresso shot. It was OK(ish) and I was happy that I had apparently fixed the machine. It was Saturday afternoon and I had remedied the problem. Or so I thought.

Fixing the Problem (For Real)

Sunday morning rolled around and the crema police was ready for some espresso goodness. To my disappointment, the pressure problem had re-appeared and it was even worse. Now, there was nothing coming from the group head, not even a small drip. No espresso for me.

I started thinking. Maybe the problem wasn’t the solenoid valve after all? What if the pump wasn’t completely broken but had some inner part damaged and thus delivered insufficient pressure? This possibility had been mentioned in at least one forum post. I ran the water circulation a few more times, listening carefully to the pump and watching its water intake. It sounded and looked completely fine. Hmm.

You know what Einstein didn’t say (but apparently someone in a meeting of anonymous alcoholics)? “Insanity is doing the same thing over and over again and expecting different results.” And yet here I was, taking the solenoid valve apart, again. Partly because I was out of other ideas and partly because I wanted to double-check my cleaning work from the day before. Imagine my surprise when I was greeted with a fresh load of sludge in the valve.

And suddenly it dawned on me. By cleaning out the sludge in the valve I had made room for new stuff to slide down from above. There was more goo sitting in the group head and once I had put the machine upright, it simply slid down and clogged the valve again. But that also meant that there was an easy fix: Just run the machine without the valve. Water would pour out of the hole and rinse out all the sludge in the process.

Now, more sophisticated espresso machines would probably have a nifty sensor that would prevent you from ever doing this. Not Miss Silvia, though; she’s simple-minded and very loyal. It’s up to you, the owner, to decide whether your creative (ab)use of the machine - or a combination of its parts - will lead to electrocution or success. I decided it was worth the risk, fitted out the back wall with a cloth (to absorb some of the water spray I was expecting) and gave it a go. And what shall I say? It was a complete and triumphant victory:

It’s a bit hard to discern in the video, so here’s a look at the stuff that came out:

The sludge floweth.

The sludge floweth.

The sludge that came out was roughly 3-4 times the amount I had cleaned out the previous day and it left me with the satisfying hunch that I had remedied the problem for real. This was confirmed when I put the machine back together and watched a healthy downpour of water coming from the group head:

Miss Silvia was good as new (no replacement needed!), I was satisfied with the outcome and ready for that Sunday espresso. With the pressure restored, it came out almost instantly with rich crema.